The top offering in the GDP pump line is the FUEL BOSS mechanical lift pump system. The FUEL BOSS is a belt driven mechanical lift pump that increase output and pressure to match engine RPM.

NOTE: Does NOT Ship To California.

Common electronic failures of the factory lift pump are eliminated. No more worries of carrying a spare pump in the tool box. The stock lift pump will now only run for a few seconds at each start. After startup the stock unit is turned off via a Hobbs pressure switch and will not run again until the next start up cycle. The stock lift pump is not required for proper Fuel Boss operation and is used only for priming the fuel canister after a filter change!

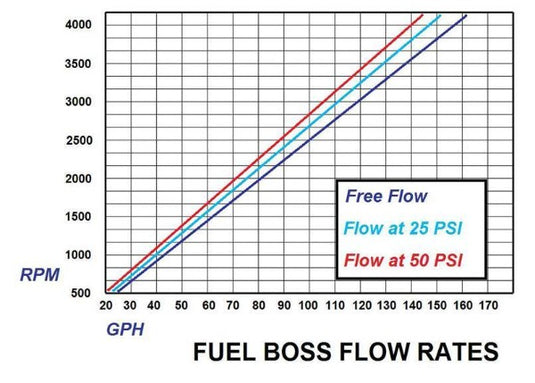

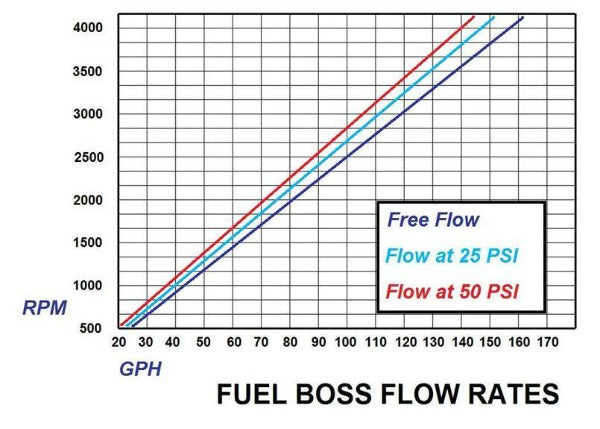

The FB-1000 pump supplied in the FUEL BOSS kit has no bearings to wear out and is a straight cut gear pump capable of pressures well above 100 psi. Running at a 2-1 reduction the FB-1000 turns only half of the engines RPM which is a mere 25% of its rated RPM at cruise. With proper belt tension the FB-1000 will easily last the life of your truck!

Extreme pump longevity is only one of the numerous benefits provided by the FUEL BOSS system. All FUEL BOSS pumps also come equipped with a 100% Viton lip seal which makes them perfect for ULSD, Bio Diesel use and Veg Oil conversions.

FUEL BOSS drive systems are comprised of high strength polycarbonate drive pulleys and nylon covered, fiberglass reinforced, neoprene belts. Belt changes are recommended at 50k to 75k intervals.

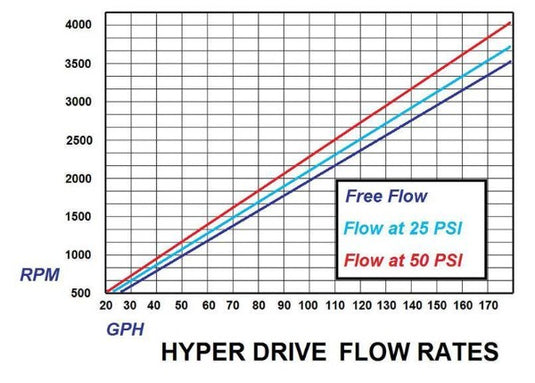

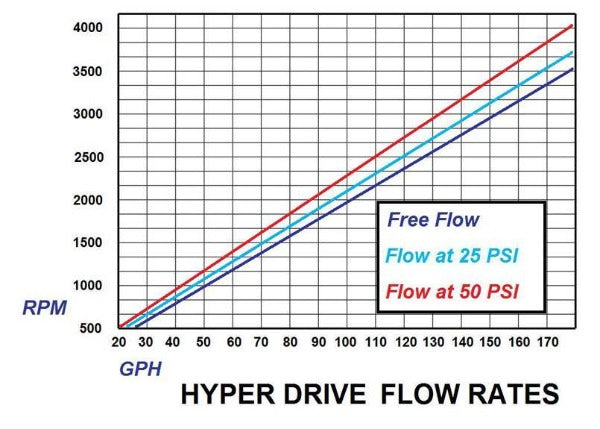

Tied to the engine’s RPM via the crank mounted drive pulley the FUEL BOSS will increase output and pressure any time you increase engine RPM. This is truly an engine driven high output system! Minimum fuel pressures at idle and maximum flow at engine redline, just the way it should have been from the factory. Tap the throttle and watch your fuel pressure gauge rise instead of fall!

The FUEL BOSS can fuel any truck from stock to the wildest, Hot Rod VP fed power plant imaginable! For extreme trucks we offer a Hyper-Drive belt and pulley combo which will increase pump speed and output an additional 20% over the stock 2 to 1 drive combo provided.

FITMENT NOTES

Only for trucks with stock harmonic balancers. Due to dimensional differences this system will not work with aftermarket harmonic balancers such as the Fluidampr brand balancers.

NOT for use on trucks with an in-tank conversion. If your truck has been converted to an in-tank pump please contact us and we will build a system for your application.

Keeping your old lift pump intact is not required BUT helps with priming the fuel system after filter changes. It also acts a a backup if the mechanical pump / pump were to ever fail.

The top offering in the GDP pump line is the FUEL BOSS mechanical lift pump system. The FUEL BOSS is a belt driven mechanical lift pump that increase output and pressure to match engine RPM.

NOTE: Does NOT Ship To California.

Common electronic failures of the factory lift pump are eliminated. No more worries of carrying a spare pump in the tool box. The stock lift pump will now only run for a few seconds at each start. After startup the stock unit is turned off via a Hobbs pressure switch and will not run again until the next start up cycle. The stock lift pump is not required for proper Fuel Boss operation and is used only for priming the fuel canister after a filter change!

The FB-1000 pump supplied in the FUEL BOSS kit has no bearings to wear out and is a straight cut gear pump capable of pressures well above 100 psi. Running at a 2-1 reduction the FB-1000 turns only half of the engines RPM which is a mere 25% of its rated RPM at cruise. With proper belt tension the FB-1000 will easily last the life of your truck!

Extreme pump longevity is only one of the numerous benefits provided by the FUEL BOSS system. All FUEL BOSS pumps also come equipped with a 100% Viton lip seal which makes them perfect for ULSD, Bio Diesel use and Veg Oil conversions.

FUEL BOSS drive systems are comprised of high strength polycarbonate drive pulleys and nylon covered, fiberglass reinforced, neoprene belts. Belt changes are recommended at 50k to 75k intervals.

Tied to the engine’s RPM via the crank mounted drive pulley the FUEL BOSS will increase output and pressure any time you increase engine RPM. This is truly an engine driven high output system! Minimum fuel pressures at idle and maximum flow at engine redline, just the way it should have been from the factory. Tap the throttle and watch your fuel pressure gauge rise instead of fall!

The FUEL BOSS can fuel any truck from stock to the wildest, Hot Rod VP fed power plant imaginable! For extreme trucks we offer a Hyper-Drive belt and pulley combo which will increase pump speed and output an additional 20% over the stock 2 to 1 drive combo provided.

FITMENT NOTES

Only for trucks with stock harmonic balancers. Due to dimensional differences this system will not work with aftermarket harmonic balancers such as the Fluidampr brand balancers.

NOT for use on trucks with an in-tank conversion. If your truck has been converted to an in-tank pump please contact us and we will build a system for your application.

Keeping your old lift pump intact is not required BUT helps with priming the fuel system after filter changes. It also acts a a backup if the mechanical pump / pump were to ever fail.