SKU: CS-CA-MS16-94

- Includes 4 Arms Pictured, 2 Upper, 2 Lower

- Re-centers front axle on 3" Suspension Systems

- Box 0.120" wall mild steel construction

- Arm centers welded off-center for tire clearance

- 35" Tire Fitment (9" Wide Wheel, 5.75" BS)

- Fits 14mm upper/16mm lower hardware - Factory bolt shank diameter

- MUST measure control arm bolts on truck to ensure correction selection

The 1994-2012 Dodge Ram 2500/3500 utilizes a 5-Link front suspension. Comprising this link system are upper and lower control arms to hold the axle fore/aft while the track bar serves as the lateral link to minimize lateral shift.

When lifting the front end of a straight axle truck, you’re essentially pushing the axle further away from the frame at ride-height. As the travel is not perfectly linear, the new ride height will set the front axle off-center unless the proper linkages are addressed.

The systems we design for these trucks range from 2.5″-3″ of front lift. Three inches of front lift equates to an axle shifted toward the driver’s side ¾” and back toward the cab ½”. Although this is perfectly operable when the factory control arms and track bar are in good condition, we recommend the purchase of an adjustable track bar to shift the axle back toward the passenger side and provide a stronger link with less deflection for the lifted application, and a set of extended control arms to shift the axle forward to its new center of travel.

The construction of these arms starts with 0.120″ Box Steel mated to in-house machined joint-cups. The mild-steel center sections are welded inboard of center to offset the link as far from the tire as possible for optimal tire clearance.

We pride ourselves on our joints. In a market abundant with hat-bushing and crush sleeve equipped arms, our spherical bearing arms are leaps ahead of the competition. As described above, the travel of the ram’s front axle is non linear. It travels up and down and back and forth. This is a non issue for a standard 3-piece hat bushing. The problem is in the substantial lateral shift of the axle thanks to the track-bar design. This side to side movement falls outside the operating range of hat bushings meant for a linear load effectively hot-spotting and egging out the bushing hole as they bind when the axle articulates.

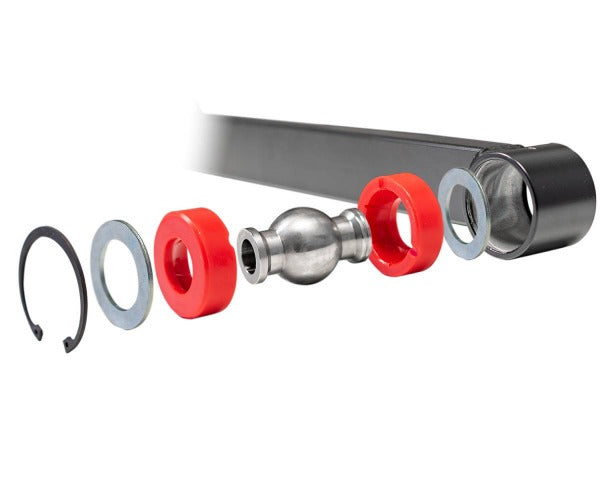

The answer? A spherical joint design allowing far more lateral misalignment in addition to the up and down/fore & aft movement. At the heart of the joint assembly, you’ll find our in-house machined a 17-4 Stainless ball center. This is surrounded by our Proprietary Bushings & Joint Washers. The assembly is preloaded into the cup and retained with a snap-ring. Last but certainly not least, a zerk fitting is added. for ease of servicing.

Over the years, we learned a LOT about bushings. Originally, we started with Currie Johnny Joints. Although they were high quality joints and better than anything on the market (at the time), there was room for improvement. We machine all the Ball Centers in-house from 17-4 Stainless bar-stock. This is a much more corrosion resistant material in addition to being higher strength. Where we saw some stress fractures in the Currie joints at the Ram torque specs, our Stainless ball center took without issue! While designing them, we took the opportunity to oversize the mating surfaces for the most contact area to the control arm frame/axle mounts. They’re substantially larger than the Currie and 0.050″ oversized from even a factory control arm!

Over the years, we learned a LOT about bushings. Originally, we started with Currie Johnny Joints. Although they were high quality joints and better than anything on the market (at the time), there was room for improvement. We machine all the Ball Centers in-house from 17-4 Stainless bar-stock. This is a much more corrosion resistant material in addition to being higher strength. Where we saw some stress fractures in the Currie joints at the Ram torque specs, our Stainless ball center took without issue! While designing them, we took the opportunity to oversize the mating surfaces for the most contact area to the control arm frame/axle mounts. They’re substantially larger than the Currie and 0.050″ oversized from even a factory control arm!

Next up, we went to work on a project with Energy Suspension designing new bushings for our ball centers. The Currie were great quality but often difficult to get grease into. It wasn’t uncommon to need to articulate the truck to line the zerk fitting port with the split in the bushings. Our new, RED bushings have grease channels engineered into all surfaces to ensure easy greasing and proper grease migration. Further, they’re not interlocked like the old bushings allowing more room for grease and easier joint articulation.

SKU: CS-CA-MS16-94

- Includes 4 Arms Pictured, 2 Upper, 2 Lower

- Re-centers front axle on 3" Suspension Systems

- Box 0.120" wall mild steel construction

- Arm centers welded off-center for tire clearance

- 35" Tire Fitment (9" Wide Wheel, 5.75" BS)

- Fits 14mm upper/16mm lower hardware - Factory bolt shank diameter

- MUST measure control arm bolts on truck to ensure correction selection

The 1994-2012 Dodge Ram 2500/3500 utilizes a 5-Link front suspension. Comprising this link system are upper and lower control arms to hold the axle fore/aft while the track bar serves as the lateral link to minimize lateral shift.

When lifting the front end of a straight axle truck, you’re essentially pushing the axle further away from the frame at ride-height. As the travel is not perfectly linear, the new ride height will set the front axle off-center unless the proper linkages are addressed.

The systems we design for these trucks range from 2.5″-3″ of front lift. Three inches of front lift equates to an axle shifted toward the driver’s side ¾” and back toward the cab ½”. Although this is perfectly operable when the factory control arms and track bar are in good condition, we recommend the purchase of an adjustable track bar to shift the axle back toward the passenger side and provide a stronger link with less deflection for the lifted application, and a set of extended control arms to shift the axle forward to its new center of travel.

The construction of these arms starts with 0.120″ Box Steel mated to in-house machined joint-cups. The mild-steel center sections are welded inboard of center to offset the link as far from the tire as possible for optimal tire clearance.

We pride ourselves on our joints. In a market abundant with hat-bushing and crush sleeve equipped arms, our spherical bearing arms are leaps ahead of the competition. As described above, the travel of the ram’s front axle is non linear. It travels up and down and back and forth. This is a non issue for a standard 3-piece hat bushing. The problem is in the substantial lateral shift of the axle thanks to the track-bar design. This side to side movement falls outside the operating range of hat bushings meant for a linear load effectively hot-spotting and egging out the bushing hole as they bind when the axle articulates.

The answer? A spherical joint design allowing far more lateral misalignment in addition to the up and down/fore & aft movement. At the heart of the joint assembly, you’ll find our in-house machined a 17-4 Stainless ball center. This is surrounded by our Proprietary Bushings & Joint Washers. The assembly is preloaded into the cup and retained with a snap-ring. Last but certainly not least, a zerk fitting is added. for ease of servicing.

Over the years, we learned a LOT about bushings. Originally, we started with Currie Johnny Joints. Although they were high quality joints and better than anything on the market (at the time), there was room for improvement. We machine all the Ball Centers in-house from 17-4 Stainless bar-stock. This is a much more corrosion resistant material in addition to being higher strength. Where we saw some stress fractures in the Currie joints at the Ram torque specs, our Stainless ball center took without issue! While designing them, we took the opportunity to oversize the mating surfaces for the most contact area to the control arm frame/axle mounts. They’re substantially larger than the Currie and 0.050″ oversized from even a factory control arm!

Over the years, we learned a LOT about bushings. Originally, we started with Currie Johnny Joints. Although they were high quality joints and better than anything on the market (at the time), there was room for improvement. We machine all the Ball Centers in-house from 17-4 Stainless bar-stock. This is a much more corrosion resistant material in addition to being higher strength. Where we saw some stress fractures in the Currie joints at the Ram torque specs, our Stainless ball center took without issue! While designing them, we took the opportunity to oversize the mating surfaces for the most contact area to the control arm frame/axle mounts. They’re substantially larger than the Currie and 0.050″ oversized from even a factory control arm!

Next up, we went to work on a project with Energy Suspension designing new bushings for our ball centers. The Currie were great quality but often difficult to get grease into. It wasn’t uncommon to need to articulate the truck to line the zerk fitting port with the split in the bushings. Our new, RED bushings have grease channels engineered into all surfaces to ensure easy greasing and proper grease migration. Further, they’re not interlocked like the old bushings allowing more room for grease and easier joint articulation.